Future generations of solid-state lithium-ion batteries based on hybrid ceramic-polymer electrolytes could offer the potential for greater energy storage, faster recharging, and higher electrochemical and thermal stability – while overcoming many of the technology challenges associated with earlier solid-state batteries.

At the Georgia Institute of Technology (Georgia Tech), researchers are working to expand their fundamental understanding of these hybrid electrolytes, the component that transfers charge between electrodes as the batteries power systems such as electric vehicles (EVs) – and are then recharged. Lithium-ion batteries widely used in today’s EVs rely on liquid electrolytes, which are susceptible to thermal runaway and fire if they are damaged.

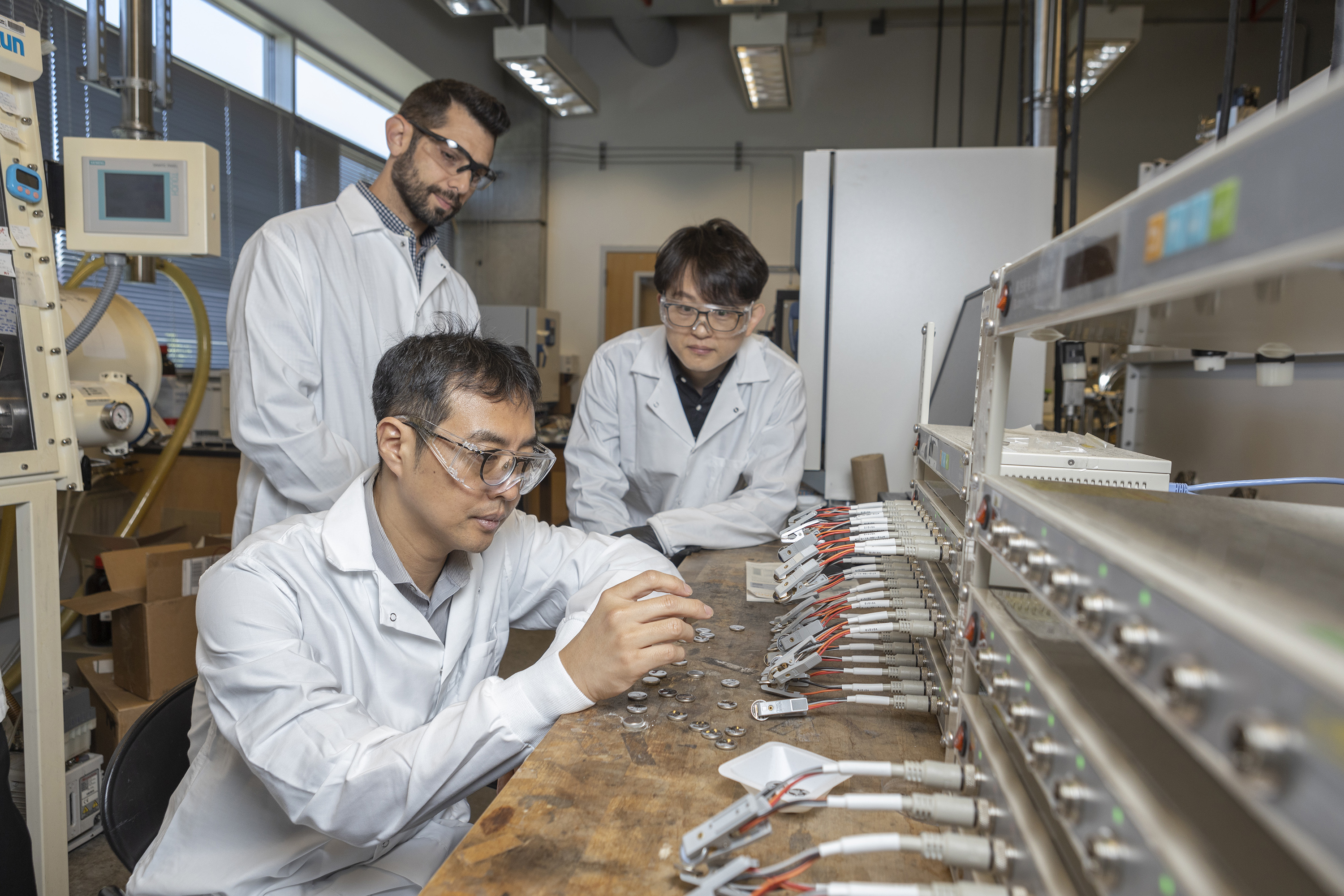

“We’ve shown that we can fabricate these hybrid, solid-state electrolytes and put them into coin cells to demonstrate high performance and high stability,” said Ilan Stern, a principal research scientist who leads battery research at the Georgia Tech Research Institute (GTRI), Georgia Tech’s applied research organization. “We’ve laid the foundation to show that we can develop innovations in solid-state batteries based on these ceramic-polymer hybrids. Our next step is to integrate the technology into pouch cells, the type of batteries used in electric vehicles.”

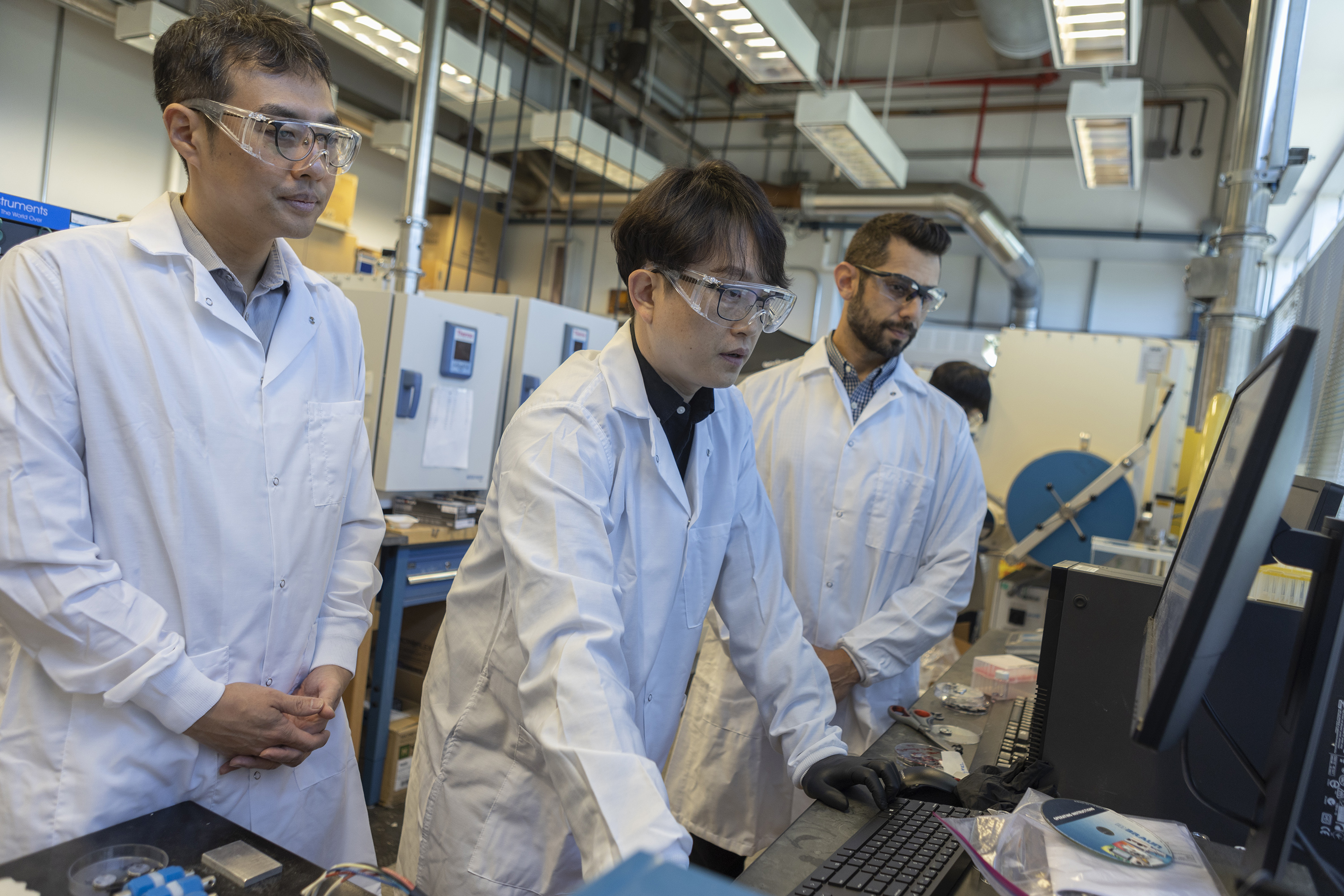

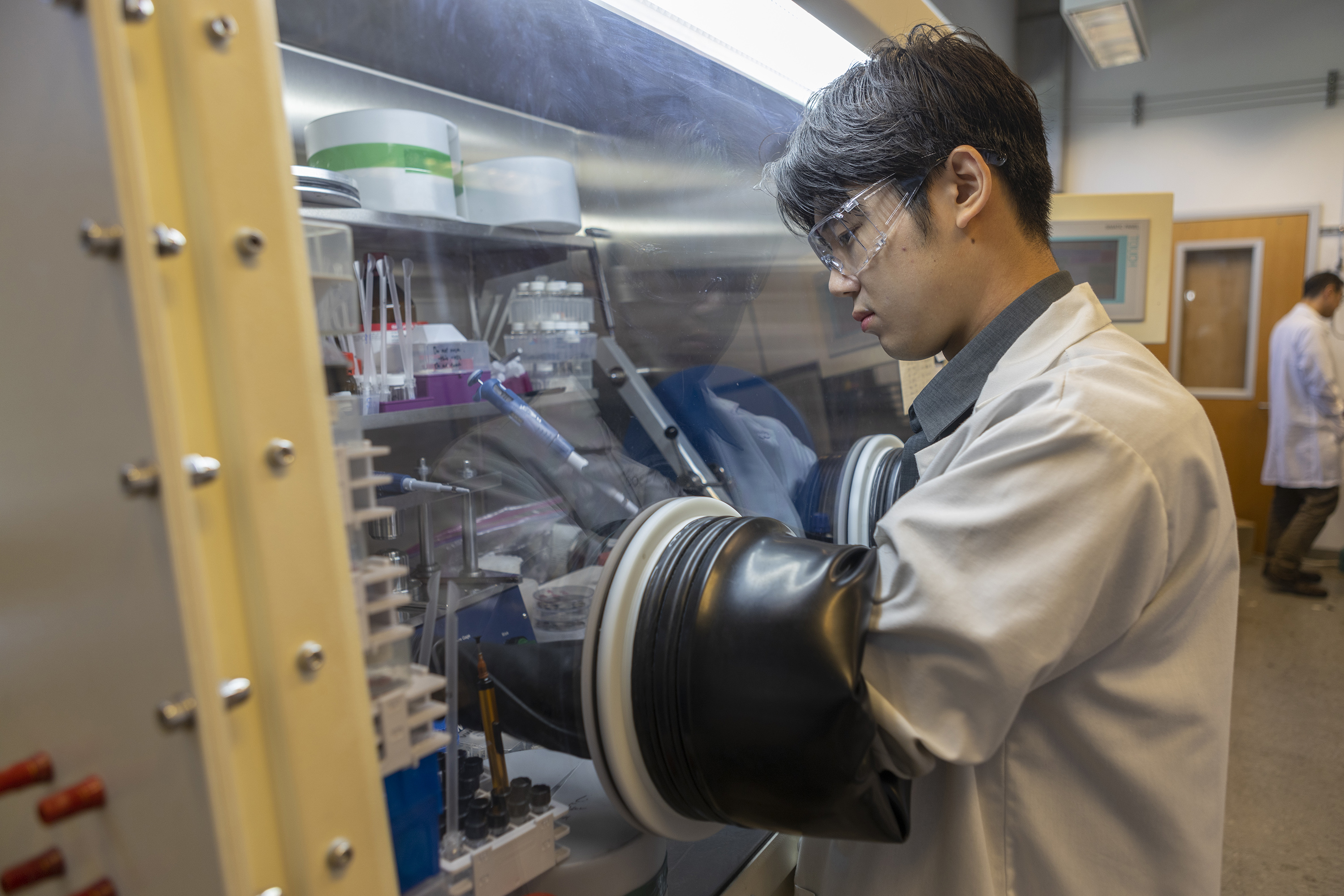

The GTRI researchers are working with colleagues from Georgia Tech’s George W. Woodruff School of Mechanical Engineering, School of Materials Science and Engineering, and the Strategic Energy Institute on research into an electrolyte known as lithium aluminum germanium phosphate (LAGP). A polymer component known as poly DOL surrounds the LAGP electrolyte, providing internal ionic conductivity that goes well beyond existing ceramic electrolytes – without the disadvantages of flammable liquids. The fabrication team and academic collaboration are led by Jinho Park, a GTRI research scientist. Synthesis of the LAGP ceramic is led by Jason Nadler, a GTRI principal research scientist.

Advantages of Hybrid Ceramic-Polymer Materials

Stern describes traditional ceramic electrolytes as similar to hard candy – think M&Ms – poured into the space between the battery anode and cathode. The hard ceramics provide safety and energy storage advantages, but are limited in how much they contact the electrodes to transfer ionic charges. Adding the polymer dramatically improves the interfacial contact between the electrodes and electrolyte while maintaining most advantages of the ceramics.

“The electrochemical stability, thermal stability and mechanical stability will be the main differences between the liquid electrolytes and these hybrids,” he said. “We’re really taking the best of both worlds. As solid-state batteries enable the use of a Li-metal anode, the ceiling for capacity is significantly higher, so we should ultimately see a dramatic increase in energy density compared to the conventional Li-ion batteries based on the liquid electrolytes.”

The hybrid ceramic-polymer electrolyte looks like a hockey puck, but will be more resistant to damage than a pure ceramic. “It will certainly be much more forgiving than a ceramic,” Stern said. “Even if micro-cracks develop, the polymer will provide the scaffolding to ensure integrity, holding it together structurally.”

Moving Ahead with Solid-State Batteries

Solid-state batteries are not yet in commercial use, but at least one EV manufacturer plans to put them into vehicles within the next few years as battery manufacturers continue to make improvements. But the technology is far less mature than existing liquid-electrolyte systems, inviting innovations such as the hybrid system the Georgia Tech researchers are working on.

The research is being supported, in part, by a $1.1 million, three-year independent research and development commitment from GTRI. “With the unprecedented federal and state investment made in Georgia for electric vehicles, battery manufacturing, and recycling, GTRI continues to build strong collaborations to help identify gaps and new business models – and to forecast the number and types of recycling plants necessary to respond to future market demands,” Stern added.

Based on encouraging results with small, laboratory-scale batteries, the researchers plan to expand their work into batteries that could be fabricated by the hundreds or thousands for further development and testing – and, ultimately, large-scale manufacturing. “As we increase our efficiency with fabrication, manufacturing costs will come down, while supply chain integration and the sustainability goals of reusability and recycling will have a big impact,” Stern said.

Model-Based System Engineering Guides the Future

Beyond demonstrating the potential for this technology, the research team also is modeling the operation of the cells to help guide future technology development and assessing the potential life cycle of the hybrid electrolyte solid-state batteries. Among the future goals are integrating the technology into supply chains that would not rely on materials sourced from conflict areas of the world, and evaluating new electrode materials such as lithium metal and silicon to replace standard graphite.

“The objective of the model-based system engineering (MBSE) task is to model expert knowledge ranging from the fabrication level to the system integration to unveil opportunities for research as well as new business models,” said Paula Gomez, a GTRI senior research engineer, and the modeling team lead.

The research team is developing models in three main areas: (1) fabrication and performance; (2) manufacturing process; and (3) reuse, refurbish, and recycling. Integrating these models involves evaluating battery efficiency and stability, cost of production, and energy consumption, as well as return on investment of recycling materials.

Though the advantages of solid-state electrolytes are very attractive, there are challenges ahead. A hybrid electrolyte system is more complicated to manufacture, and the electrical, mechanical, and chemical interactions between the materials must be thoroughly studied. “The more complexity you have, the more issues you have to understand,” Stern said.

Military and Economic Development Applications

GTRI is known for its support of national security through research sponsored by U.S. Department of Defense agencies. Stern expects the improved solid-state battery technology will ultimately find its way into military gear carried by soldiers and future generations of electrically powered military vehicles.

The work also supports economic development for the state of Georgia, which is rapidly becoming a hub for electric vehicle and battery manufacturing.

“Georgia is becoming the epicenter of the electrification revolution with vehicle makers such as Rivian and Hyundai, battery companies such as SK, FREYER Battery, and recyclers such as Ascend Elements,” Stern said. “Georgia Tech is contributing to the state’s economic development by helping drive that innovation.”

Battery Day Demonstrates Interest

A recent “Battery Day” held March 30 at Georgia Tech highlighted the broad research collaborations already underway. Led by Matthew McDowell, associate professor in the George W. Woodruff School of Mechanical Engineering and the School of Materials Science and Engineering, the event attracted more than 230 energy researchers and industry participants.

Beyond those already mentioned, the hybrid battery project includes Michael Shearin, Richard Wise, John Hankinson, Matthew Swarts, Khatereh Hadi, Milad Navaei, and Jack Zentner from GTRI.

Writer: John Toon (john.toon@gtri.gatech.edu)

GTRI Communications

Georgia Tech Research Institute

Atlanta, Georgia

The Georgia Tech Research Institute (GTRI) is the nonprofit, applied research division of the Georgia Institute of Technology (Georgia Tech). Founded in 1934 as the Engineering Experiment Station, GTRI has grown to more than 2,900 employees, supporting eight laboratories in over 20 locations around the country and performing more than $800 million of problem-solving research annually for government and industry. GTRI's renowned researchers combine science, engineering, economics, policy, and technical expertise to solve complex problems for the U.S. federal government, state, and industry.